Description

|

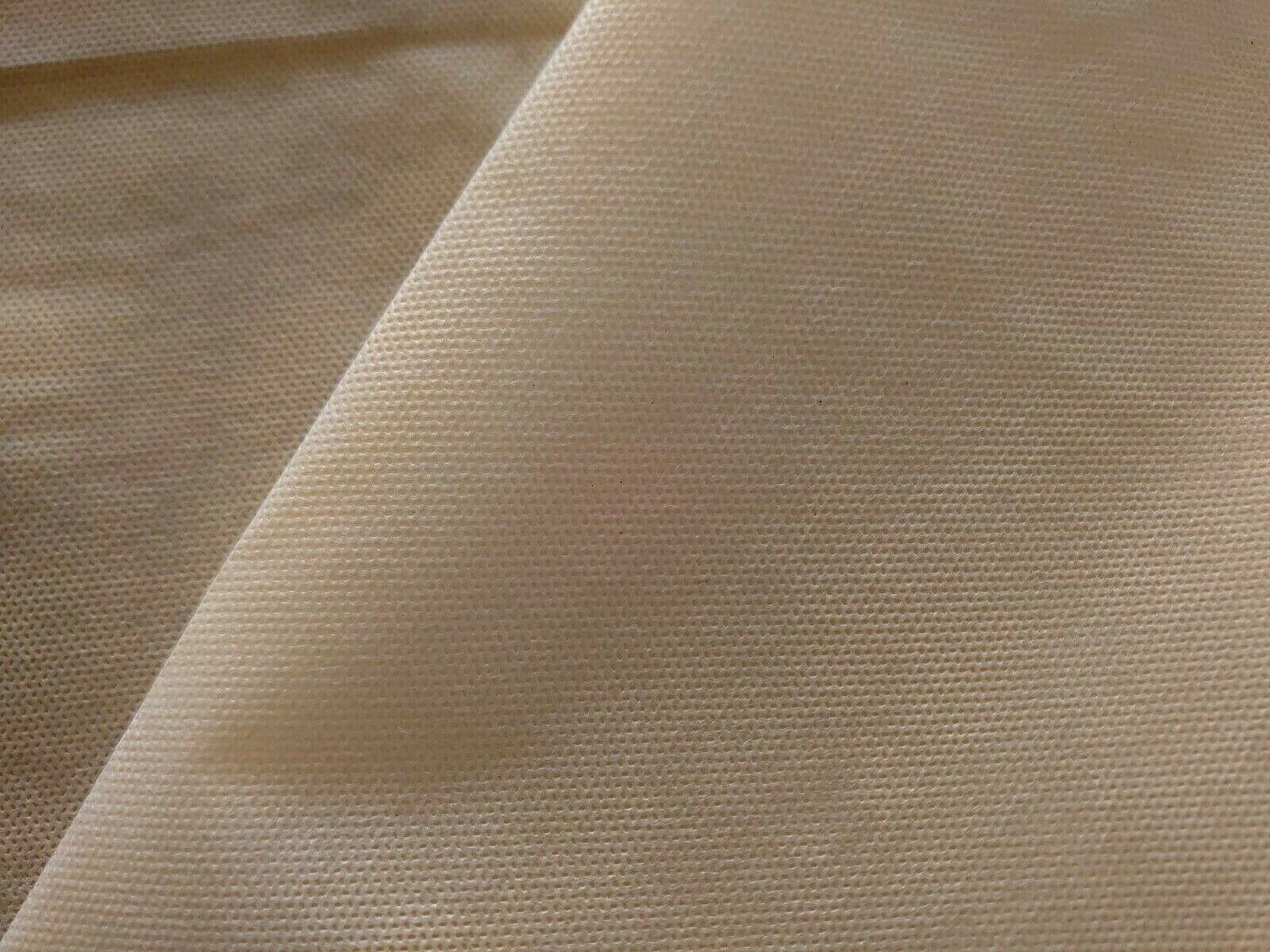

Cream spun 100% polypropylene nonwoven breathable filter material fabric W160cm per metre

High quality polypropylene non-woven material, ideal for making reusable face masks or filter inserts for pocket-style cloth face masks. Polypropylene is popular with face masks and reusable bag makers. This is the same material used for single-use surgical masks (not to be confused with N-95 respirators), and is a good non-woven layer to add to cotton fabric for homemade masks that helps stop the spread of particles and moisture much better than a woven cloth. Highly breathable and comfortable. Strong, soft, flexible. – The fabric will be sold per metre in one continual length. So for example, if you type 3 into the unit box you will receive 3 metres in one length This material IS washable for a dozen or more uses, but high heat can melt it. Washing in cold/warm soap and water and air drying is ideal. 2. Polypropylene is perfect as a replaceable filter layer in pock-style masks. It helps stop particle spread much better than a woven cloth. 3. Polypropylene should not be sewn into masks being donated, as the sterilization process will melt it. WASHABLEHand washes in cold/warm water, line dry. Can be machine washed on low heat, launders best when sewn in between layers of stabilizing fabric such as cotton. ANTI-MICROBIALLike other synthetic fibers – nylon, acrylic and polyester – polypropylene fibers are not attacked by bacteria or micro-organisms; they are also moth-proof and rot-proof and are inherently resistant to the growth of mildew and mold. IS NOT ANTI-VIRAL ENVIRONMENTALLY RESPONSIBLERecyclable, ecologically friendly. Incinerates to trace ash with no hazardous volatiles. EFFECTS OF HEATThe melting point of polypropylene is about 165°C with maximum processing (softening) temperature of approximately 140°C. Prolonged exposure to elevated temperatures will cause degradation of the fiber, but anti-oxidants are incorporated in polypropylene fibers to protect them during processing and at normal service temperatures. Nevertheless, this temperature is sufficiently high to enable the fiber to be processed satisfactorily in almost all normal manufacturing processes. The lower softening temperature is of little consequence in service except that when ironing, it is necessary to control the temperature so as not to exceed 120°C. Small free samples are available on request |

||||||||||||||||

Only logged in customers who have purchased this product may leave a review.

There are no reviews yet.